|

|

WH type fluidized hot air furnace with production of 1800T powder per day

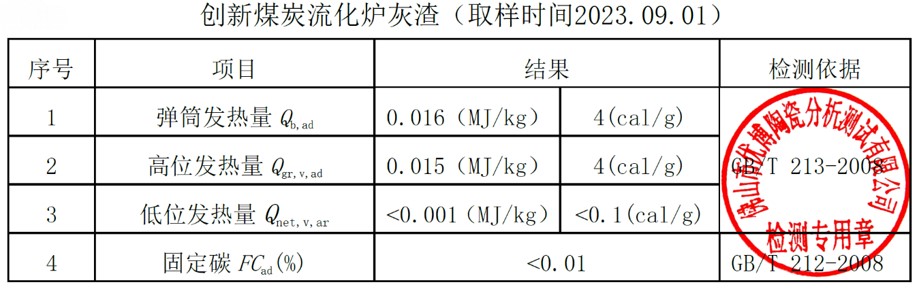

The WH type coal fluidized hot air furnace of Welkin is particularly. Its excellent performance and technical indicators will help ceramic enterprises further save energy and reduce consumption, and increase product competitiveness. Compared with the old type coal slag fluidized hot air furnace, the advantages of the WH type fluidized hot air furnace are: 1. Save over 50% of floor space. 2. Save over 40% on equipment investment and save over 85% on civil engineering investment cost. 3. The initial start-up speed of this equipment is fast (it only takes 1 hour from igniting firewoodto producing qualified powder, and can also be upgraded to a diesel automatic ignition system). 4. It can be equipped with an integrated denitrification system, fully meets the environmental requirements for emissions. 5. Suitable for on-site renovation of drying tower hot air furnace for all new and old factories. 6. It can achieve mixed combustion of coal, biomass particles, coal tar, and production wastewater. 7. A brand new process with higher combustion efficiency and easy operation. 8. The almost completely burned furnace bottom and cyclone dust removal ash, with a fixed carbon FCad content <0.01%, will not affect the quality of any type of powder. 9.The automated electronic control system ensures safety through full chain operation, with real-time feedback of data from various control points and alarm points, which can be viewed by mobile phone and computers at any time. |